Thinking Outside the Pot: The Bond between Taiwan and the Steam Rice Cooker

In Taiwan, using a steam rice cooker is an everyday experience. However, up until the 1960s, the big stoves, briquette stoves, and kerosene stoves still enjoyed widespread popularity. How did the steam cooker eventually step into our homes and become one of our essential kitchen appliances? This article will present a few facts about the steam cooker, examining the history of its growing popularity in Taiwan.

By Qin Xian Yu (秦先玉)

Translated by Hon Yee Tong

Edited by Sabrina Teng-io Chung

This article first appeared on Sci-Tech Vista and was translated and published with the permission of the original publisher.

HOW DID THE STEAM COOKER ENTER TAIWANESE HOMES?

From the perspective of Taiwan’s culinary history, the steam rice cooker (電鍋) was initially characterised as a technologically backward appliance, though it continued to receive consumer support. When it was first introduced in the late 1960s, Taiwanese consumers were not particularly enthusiastic about it. By the mid-1970s, however, it became the primary cooking appliance in urban areas.

Thereafter, “technologically advanced” and energy-saving models successively appeared, such as the electric rice cooker (電子鍋) imported from Japan in the 1970s and the Taiwanese manufactured electric rice cooker after 1983. Even so, until the end of the 1980s, steam cookers and electric rice cookers both had considerable market share and were close rivals.

The Taiwanese steam cooker occupied a special position in the national imagination. Dubbed the “predecessor” of the Taiwanese steam cooker, the 1995 Japan-manufactured Toshiba’s ER-4 “Automatic Electric Rice Cooker” fell out of favor and was “evicted” from Taiwan by 1975.

In Hong Kong, Shun Hing Hong (信興行), the sole agent for Panasonic products in Hong Kong and Macau, imported Japan's Matsushita direct heating “automatic heat retaining electric rice cooker” in December 1959. After continuous improvement, it was widely adopted by Hong Kong consumers. Later on, these direct heating rice cookers were promoted to markets throughout China and Southeast Asia, becoming the mainstream appliance for cooking rice in Asia.

First Generation Steam Rice Cooker from Toshiba (Source: Toshiba Science Museum)

Even though indirect heating steam cookers occupied a unique position in Taiwan, it has never been thoroughly taken into serious consideration in academic discourses. Experts and scholars from the design and electronics industry generally believe that Taiwanese steam cookers were created after the image of Japanese models. Lacking in-depth analysis of the steam cookers’ design, such explanation conceals the multi-faceted relationship between the steam cooker and Taiwanese society.

Hence, this essay seeks to shift the perspective from Japanese innovation to Taiwanese popularization, with an emphasis on how the steam cooker became so ingrained in Taiwanese households from the 1950s to 1970s. In this complicated process, we discuss how industrial electronics engineers accommodated a range of factors--from Taiwanese food culture, users’ feedback, processing technologies, power supply, and other conditions--to develop models that cater to the specificities of Taiwan’s culinary culture. Finally, we will venture “out of the pot” to explore new possibilities to understand the mutual imbrications of the steam cooker and Taiwanese society.

TAIWAN’S FIRST STEAM RICE COOKER

Dissected steam rice cooker on display at the National Taiwan Science Education Center ( Photo Credits: Kong Jing Hui)

Even though the Tatung Company is almost synonymous with steam cookers today, in the 1960s, there were over 30 steam rice cooker manufacturers. For instance, the relatively lesser known “Crown Brand automatic rice cooker ” (皇冠牌自動炊飯器) was manufactured by Taipei City’s Yungtay Engineering Co., Ltd (永大電機工業社) and entered the market in 1958. This rice cooker was introduced before Tatung Company’s steam cooker, and around 4 to 5 years earlier than the direct heating steam cookers (the heating element of this type of rice cooker is directly in contact with the inner pot containing the rice). The indirect heating steam cooker thus had a first mover advantage.

The indirect heating steam cooker separates the inner pot containing the rice from an outer pot containing the heating system. This type of rice cooker has 4 components: the heating element, the automatic on-off switch, and the inner and outer pots.

The core technique in manufacturing the parts for steam cookers lies in using machine tools such as lathing and punching. Therefore, the thirty-odd early steam cooker manufacturers had two features. Geographically, their locations were primarily concentrated in Taipei, Taichung, and Tainan. In terms of their industrial orientation, half of them were founded after World War II, while the rest were converted from metals and machinery factories. They were manufacturing kerosene stoves, electric fans, motors, transformers, and other tools, and their pre-existing technological foundations allowed them to transition smoothly to steam cooker manufacturing.

As design scholars pointed out, the TAC-6 manufactured by Tatung Steel Machinery Co. Ltd (大同製鋼機械公司) in 1960 “plagiarised” everything from Toshiba’s “RC-6K fully automatic steam cooker”, including its functions, external appearance, and colour scheme. However, this was not an exceptional case. At that time, Toshiba had not applied for a patent in Taiwan yet; in other words, their technology was shared by the market from the beginning. In such a situation, as an engineer mentioned: “every company’s rice cooker probably plagiarised from each other; each was slightly different, and some were even completely the same, but with a different brand name”.

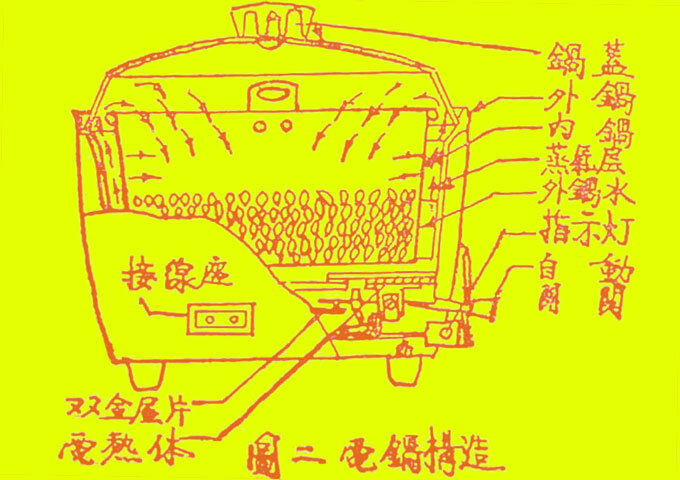

Construction diagram of Tatung steam rice cooker TAC series (Source: Tatung Bimonthly, vol. 45, no. 4: 1963, 13)

HOW DID TATUNG BECOME SYNONYMOUS WITH THE STEAM RICE COOKER?

Historians of western technology have called into question historiographical perspectives that privilege the question of “origins”, arguing how such perspectives can foreclose other research directions. A focus on the question of “technology diffusion” instead can illuminate the historical emergence of a blooming Taiwanese market for steam rice cookers in the earlier years. Such a focus reveals the emptiness of the question of “origins” with regard to which rice cooker was “Taiwan’s first”. It also points to the inadequacy of such origin-focused historiographical perspectives in understanding the global history of technology.

Readers would nevertheless want to pursue the question: with over 30 competitors, how did Tatung’s steam rice cooker come to establish such strong emotional ties with Taiwanese households and kitchens? We can try to answer this question from a technical perspective. In an era where everyone was imitating the Japanese steam cooker, competition revolved around who could copy faster and better.

From this perspective, Tatung indeed had more advantages. After World War II, it established a solid foundation in processing technology due to its electric fan manufacturing. During the first phase of Taiwan’s economic development plan, it was selected among numerous manufacturers to receive U.S. aid and set up an electric watch factory, collaborating with Japan’s Toshiba and renewing its hardware processing technology, equipment, mass production methods, and more.

In a market saturated with many indirect heating steam cooker manufacturers, the above reasons explain why Tatung swiftly became the market leader. From another perspective, most of the other manufacturers relied on private investment, equipment, and technology.

ENTERING THE POT: THE STRCUTURAL CHANGES OF THE STEAM RICE COOKER

The domestication of steam rice cooker manufacturing technology is a key factor contributing to its replacement of Taiwan’s other cooking appliances. Not many manufacturers still retain blueprints of the parts and moulds used in steam cookers. However, numerous manufacturers were copying each other’s designs, using Tatung’s TAC-6 (and TAC-8) as the main reference and supplementing it with other manufacturers’ designs. The Tatung steam cooker has four interesting modifications distinguishing it from Toshiba’s ER-4 model, namely the steaming accessories, the power-saving model, the temperature setting at 230 degrees Celsius, holes drilled in the lid, and three additional inner pot grooves.

This comparison reveals the differences in culinary culture, processing technology, and socio-economic background from which the two models of steam cookers emerged. It also reconstructs the history of how the science and technology of steam rice cookers was disseminated and domesticated.

1. The Ties between Steaming Accessories: Local Culinary Cultures

Toshiba’s ER-4 accessory components include an extension cord, 2 divided inner pots, and a measuring cup. The 2 inner pots allowed one to cook rice and miso soup simultaneously, and were one of the selling points emphasised by ER-4’s advertisement campaigns: “Wide range of uses: Other than rice cooking, its function also covers water boiling, steaming basket usages, chawanmushi-making, and more”. Afterwards, Toshiba introduced 4 divided inner pots in the 1960s, emphasising that “rice cooking, soup making, dishes warming, done all at once”.

From the 1960s, Japan started to build danchi (collective national housing). The housing units were mainly occupied by nuclear families, and the family housewives became an important target when Toshiba was promoting its electric rice cooker.

Two inner pots of Japan’s Toshiba ER-4 automatic electric rice cooker (Source: Toshiba Science Museum)

Using the nuclear family as an example, if the 2 or 4 divided inner pot function was used in cooking simultaneously, there would clearly not be insufficient space to make rice for the whole family. Therefore, the 4 divided pots were primarily used for food steaming and soup making. An advertisement for the 2 divided inner pots provided the best illustration. It shows two children, one scooping rice into a bowl while the other is drizzling curry sauce onto a bowl of rice.

Advertisement of Toshiba’s automatic electric rice cooker with two inner pots (Source: Toshiba Science Museum)

At that time, Taiwan’s briquette stove, kerosene stove, and stove cooker featured 3-in-1 functionality—they could cook rice, make dishes, and boil water. ER-4’s “wide range of uses” functionality thus occupied a central position in the diffusion of technology from Japan to Taiwan. The design changes in Toshiba’s divided pots became a feature that Taiwan’s steam rice pot manufacturers fought to adopt.

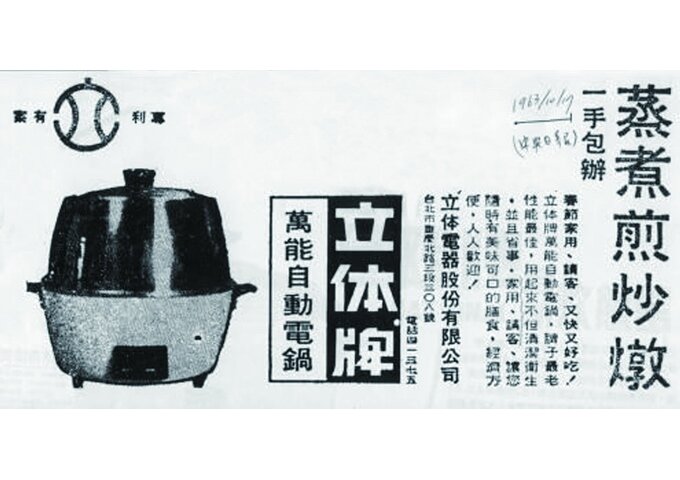

Tatung had 2 and 4 divided upper pots, and Tatung’s arch-rival Fuguei (富貴牌) also introduced 4 divided upper pots. To enhance its steaming capabilities, an engineer who left Tatung to set up a separate brand called Liti (立體牌) even increased the height of the cooker to increase the space for steaming and stewing.

Advertisement of Fuguei’s 4 divided upper pots steam rice cooker (Image: Central Daily News, May 22, 1962, First Edition)

Advertisement of Liti’s automatic steam rice cooker (Image: Central Daily News, October 17, 1963)

However, in the steam rice cooker’s “technology diffusion” phase, the engineers were already adjusting the design and functions to accommodate Taiwanese culinary culture. In Taiwan, the upper inner pots were separate from the main inner pot, and could be used together with or separately from the inner pot.

There were two reasons for this. Firstly, steam cookers sought to replace solid fuel cooking systems (固體燃料炊煮系統), which was used to cook rice on its own to keep the fragrance intact. To prevent the steamed dishes’ taste from seeping into the rice, the manufacturers adopted a design that departed from Japan’s “sauce and rice flavour mixing” approach. Secondly, the power supply in Japan in that era was adequate, whereas Taiwanese families only had electric supply within the 5-10 ampere range. Due to considerations about the power supply and electricity fees, steaming and cooking simultaneously was a more palatable option.

2. Promoting Power-Saving Models Due to limited power supply: Aggressive competition between big manufacturers

Throughout the 1950s, demand for electricity outstripping supply was an unsolved issue. There were periods when there were rotating power outages or electricity usage limits during peak hours, power saving and other policy measures. Due to limitations in power supply, and to vie for more users, Taiwanese steam cooker models and types had to be more diversified than Japan’s Toshiba models. This also explains why many steam rice cooker advertisements emphasised that they were the “most power-saving” models.

In the 1960s, Tatung’s indirect heating steam rice cooker models’ numbers represented their power consumption. TAC-8 and TAC-8s were two models that could cook ten-person servings. The two models could cook the same amount of rice, but the former’s electric power was 800 watts while the former was 600 watts. In addition to consuming less electricity, it also took less time to cook rice.

Based on interviews with an engineer, this design was created to accommodate the electricity capacity limits of families at the time. If a typical family with a 10-ampere electric meter used an 800-watt electric rice cooker, it would affect other electric appliances like the lighting and the iron, causing the circuit breaker to trip. This necessitated the introduction of the 8s power-saving model. This is also why urban inhabitants were the first users of the indirect heating steam cookers.

Accessories of Tatung’s indirect heating steam rice cooker (Source: Tatung Bimonthly, vol. 46, no. 1: 1964, back cover)

3. Culinary Habits, Technology Processing, and Higher Temperatures

The steam rice cooker’s mechanism went through numerous revisions, such as temperature adjustments. To regulate the development of household appliance manufacturing, the Industrial Development Investment Center of the Executive Yuan’s US Aid Utilisation Committee (行政院美援運用委員會工業發展投資中心) commissioned electrical experts More, Fumino, and Goro from Japan’s Shibaura Electric Co., Ltd to come to Taiwan. The three experts arrived on 11 February 1962 to launch an official 13-day investigation.

In the investigation report, they recommended that accommodating Taiwanese staple foods and suiting Taiwanese lifestyles should be the foremost considerations in the future development of Taiwanese kitchen appliances. When discussing steam rice cookers, they gave special applause to Tatung’s steam cooker, stating that it complemented the taste of Taiwanese rice by raising the highest temperature setting to 230 degrees Celsius instead of the 180 degrees Celsius used in Japan.

Unlike Japan, which mainly consumed Calrose rice (蓬萊米), in 1960s Taiwan, new rice, old rice, Indica rice, and Calrose rice were all being consumed. The engineers interviewed mentioned that the different rice breeds had different water absorption rates. Other than adjusting the amount of water in the outer pot, setting the temperature higher also ensured that every type of rice could be cooked properly.

Based on the principles of the indirect heating steam cooker, the temperature could affect the condition of the cooked rice. Setting the temperature higher could create an effect similar to baking so as to better bring out the rice fragrance. This “baking” effect is closer to the flavour produced by the stoves and briquette stoves in Taiwan at that time.

Increasing the temperature value was also linked to the processing technology standards in Taiwan at the time. According to research and development records from Japan’s Toshiba, the temperature value to cook rice has to take into account the conditions for heat transfer, including the inner pot’s material, dimensions, shape, thickness, processing refinement, electric heating element and so on. The temperature value for cooking rice, processing technology, and structural design were the three intertwined elements closely affecting one another.

A highly experienced engineer responsible for the steam cooker production line believes that early processing technologies were crude, and when casting the aluminium pots the thickness could not be evenly controlled and standardised. A thicker aluminium pan could absorb more thermal energy, and took longer to cool down. Therefore, to ensure that the rice is fully cooked, the temperature was adjusted to be higher than in Japan, to conform to the needs of Taiwan’s thicker pots.

This demonstrates how the engineers’ imitation process considered the differences between Taiwanese and Japanese processing technologies, adjusting the initial ER-4 design to attain a “production-ready” standard and rise to the challenge of a lack of standardisation in production.

4. Following User Feedback: 3 Additional Openings for the Pot Lid and 3 Grooves for the Inner Pot

According to the oral interviews conducted by Ming-Tang Wang (王明堂) and Wan-Lai Yu (游萬來), senior employees at Tatung mentioned that after a replica of the steam rice cooker was made, they noticed that steam would spatter out of the pot lid. This was because when the technology was diffused, the voltage in Japan (100V) was lower than in Taiwan (110V), and the solution was to make the pot lid heavier.

A similar issue with the pot lid reemerged in the 1960s to 1970s. With advancements in processing technology, the lid became lighter and thinner. For users, the lighter lids would still “jump and pitter-patter”. Finally, the engineers drilled a hole at the side of the lid, so that when the steam accumulated to a certain level in the rice cooker, it could escape through this notch, reducing the discomfort arising from the vibrations and sputtering steam.

Drilling a hole in the lid was developed precisely due to technological limitations in the 1960s and user intervention. Similar reasons led to another design alteration - the addition of 3 more grooves in the inner pot on 29 November 1970. In 1969, the outer pot casting and turning machine were replaced with newer versions, resulting in changes to the machining of the outer pot’s surface, which affected the amount of contact with the inner pot.

Without the guidance of Toshiba’s technicians, engineers could only implement improvements after the steam rice cooker was manufactured, and user feedback indicated that even with the rice cooked, the automatic switch would not flip. The addition of the three grooves to the inner pot was to adjust the amount of contact between the inner pot and outer pot so that there could be optimal heat transfer between the two pots and the best cooking and steaming function.

Simply put, electric manufacturers in Taiwan at the time had innate difficulties, lacking Toshiba’s original factory blueprints, data on the heat conductivity between the inner and outer pot surfaces and other statistics and information, and a lack of experience in manufacturing electric cooking appliances that Toshiba had accumulated over the years. In addition, in the technology diffusion process, the engineers also had to consider Taiwan’s power supply policy, processing technology limitations, culinary culture, user suggestions, changes to and renewal of manufacturing and casting machinery facilities, and other such conditions, and adjust the diffused technology accordingly.

COMING OUT OF THE POT: THE RELATIONSHIP BETWEEN THE RICE COOKER AND SOCIETY

This essay surveys the historical shifts in steam rice cooker manufacturing, from the phrase of “Japanese innovation” to “Taiwanese popularization”. It has sought to recreate the stages of the steam rice cooker’s propagation and the engineers’ and production units’ problem-solving abilities, presenting how users intervened in rice cooker development and how local and social conditions of the users influenced design changes.

The steam rice cooker originated from Japan but gained widespread popularity and usage in Taiwan. As the British historian of technology David Edgerton pointed out, the extent a technology is chosen and implemented varies across space and time. Therefore, this essay aims to reconstruct the history of the steam rice cooker, decentering Japan as the origin of technological innovation. Instead of focusing on the rice cooker’s relationship with Japan’s economic growth, it attends to the steam rice cooker’s impact on Taiwanese society, examining how it managed to become an indispensable part of the Taiwanese kitchen.

This new perspective echoes the view of Edgerton who maintains that an origin-centered historiographical perspective hinders the development of historical narratives that attend to “technologies in use.” He advocates research centred around the usage of technology, building a bottom-up perspective of the history of science and technology.

Next, this essay also challenges Taiwanese design scholars’ assessment of the steam rice cookers in Taiwan, an assessment that puts emphasis on the “origin” and “replica” relationship between Japanese and Taiwanese rice cookers. This essay shifts discussion from a Japan-centered perspective, focusing on the popularization and adaptation of the steam rice cooker in Taiwan. Throughout the various stages of the steam rice cooker’s popularization, Taiwanese engineers’ and consumers’ brought new “innovations” to technology. As Edgerton mentions, innovation often originates from the “technologies in use” and the peculiar problems arising from such usages.

Finally, “coming out of the pot”, this essay raises new possibilities to understand the relationship between the steam rice cooker and society. For a long time, popular belief may suggest that the introduction of the steam rice cooker simplified the domestic chores of housewives, allowing women to step out of the kitchen, altering the structure of Taiwan’s employment market, and promoting gender equality. In actual fact, from 1964 to 1973, the employment rate of Taiwanese women rose because of industrialisation and an increased demand in the labour market. My assessment of the steam rice cooker is a rebuttal, demonstrating that many hidden aspects of the relationship between the steam cooker and society can be revealed only by discarding notions of technological determinism.

The introduction of the steam rice cooker simplified the domestic chores of Taiwanese housewives, allowing them to step out of the kitchen (Source: Tatung Bimonthly, vol. 53, no. 19 (1971): 21 )

Having read this reassessment of the various stages of the steam rice cooker’s technology diffusion, adaptation, and popularization, readers should understand that a more nuanced understanding of the relationship between the steam rice cooker and society requires further clarifications about the social conditions of the user country. For example, one might consider the lifespan of a steam rice cooker, from its manufacture, production, sales, to usage. What might be the factors preventing women from participating in the domestication of technology as the engineers and repairmen did? Did restrictions on manufacturing and production manifest in the design of the steam rice cooker? And did that determine the engineers’ imagination that housewives would be the appliance’s target users from the beginning?

It is only by clarifying these questions can issues regarding the social influence of the domestication of steam rice cookers—such as the division of household labour, the professionalisation of housekeeping experts, and the inputs of female users—be comprehensively understood.